I once walked up to what I thought was a Ford 9N, ready to buy it, only to be told it was actually an 8N. Same paint, same grille, same problem many buyers still face today.

If you’ve ever confused a Ford 8N vs 9N tractor (or thrown the 2N into the mix), you’re not alone. These three models form the legendary Ford N Series, arguably the most iconic American tractor line ever produced and they look so similar that even experienced farmers get them wrong. Fresh paint jobs, decades of parts swapping, and misleading seller listings have turned what should be a simple purchase decision into a minefield of confusion.

In this guide, you’ll learn how to instantly identify which N-Series tractor you’re looking at, why the 8N commands $1,000-$2,000 more, and which model actually fits your needs. Whether you’re buying your first tractor or identifying what’s in Grandpa’s barn, we’ll cut through 80 years of confusion.

Key Takeaways

- The Ford 8N and 9N look nearly identical, but differ in transmission, hydraulics, and electrical systems.

- The 8N is more user-friendly, with a 4-speed transmission and improved hydraulic control.

- Ford 9N tractors are typically cheaper, but lack features many modern users expect.

- The 8N usually sells for $1,000–$2,000 more due to better usability and demand.

- Correct identification matters—repaints and swapped parts often lead to mislabeling.

- Quick Reference: Ford 8n vs 9n Cheat Sheet for Field Identification

- The Mechanical Face-Off: Why the 8N Commands a Premium Price

- Understanding the 2N: The Wartime Tractor That Confuses Everyone

- The "Frankenstein" Factor: What 80 Years of Parts Swapping Means for Buyers

- Modern Usability Guide: Which N-Series Tractor Matches Your Actual Needs?

- Critical Safety Warning: The Live PTO Issue You Must Understand

- Buying Guide: What to Check Before Handing Over Cash

- Conclusion: Making the Right Choice for Your Needs

- Frequently Asked Questions

Quick Reference: Ford 8n vs 9n Cheat Sheet for Field Identification

Before we dive deep into mechanical differences, let’s solve the immediate problem: you’re standing in front of a tractor (or looking at fuzzy photos in a Craigslist ad), and you need to know what you’re dealing with. Here are three foolproof identification methods that work even when the paint is wrong and the seller doesn’t know what they’re selling.

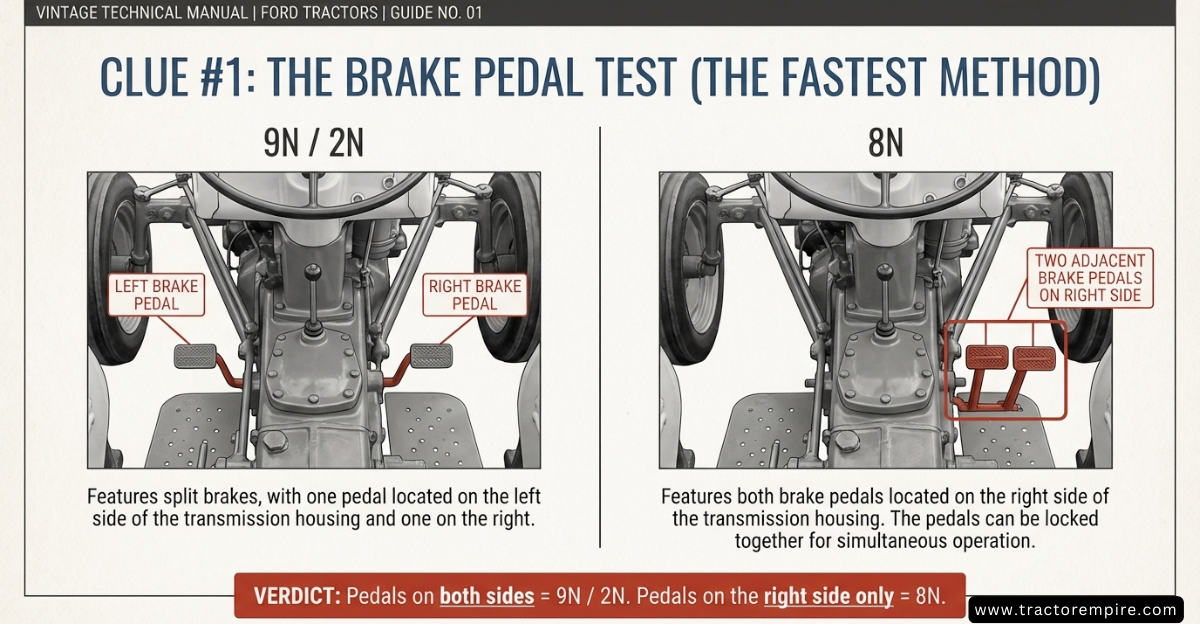

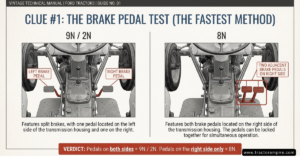

The Pedal Test (100% Accurate Every Time)

This is the fastest, most reliable way to distinguish between these Ford tractors:

Ford 9N and 2N: Brake pedals are split, one brake pedal on the left side of the transmission tunnel, one on the right side. This split-brake design meant you could lock one rear wheel while turning to make tighter turns, especially useful when plowing.

Ford 8N: Both brake pedals are positioned on the right side of the transmission. You can actually lock them together with a latch for road travel. This improved design gives you better steering control and safer highway operation.

Walk up to any N-Series tractor and look down at the pedals. If you see brakes on both sides, it’s a 9N or 2N. If both brakes are on the right, it’s an 8N. No exceptions, no confusion.

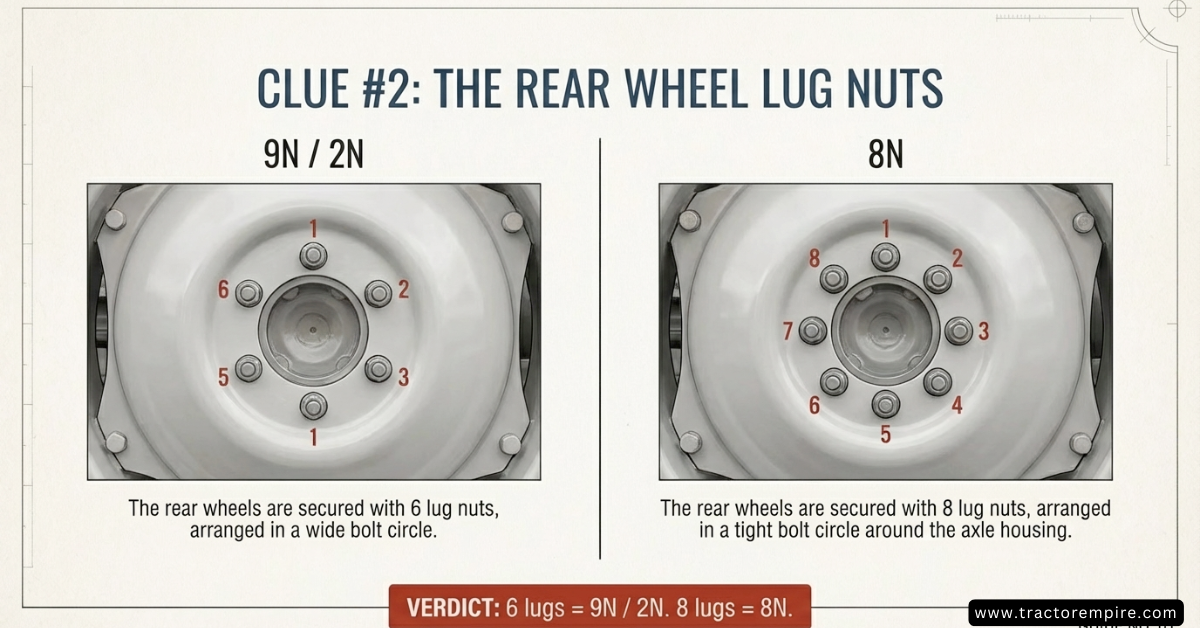

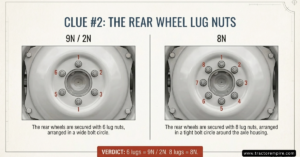

The Lug Nut Count Method

Flip your attention to those massive rear wheels:

9N and 2N tractors: 6 lug nuts holding each rear wheel, arranged in a larger diameter circle

8N tractor: 8 lug nuts per rear wheel, arranged in a smaller, tighter circle

The 8N’s eight-lug design isn’t just about identification, it’s a stronger hub system that handles heavy implement loads better. Those two extra lugs translate to real-world durability when you’re pulling a loaded hay wagon or running a heavy bush hog through tough brush.

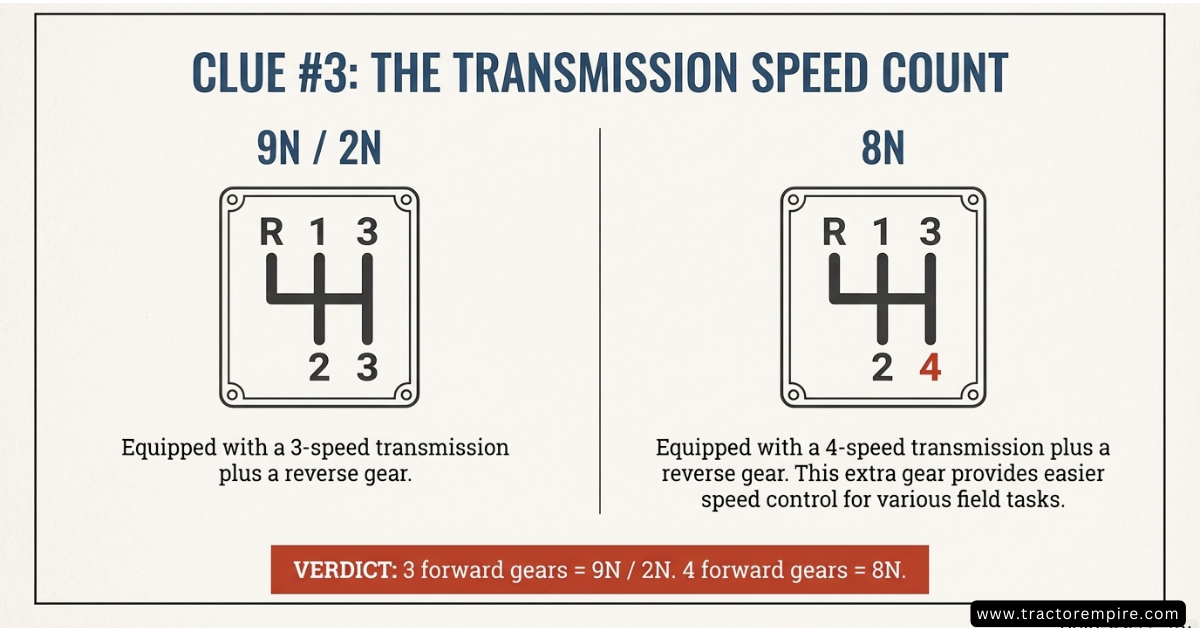

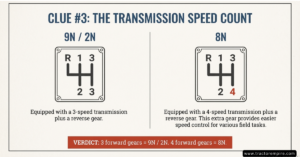

The Transmission Shift Pattern

Look at that gear shift lever sticking up from the transmission:

9N and 2N: 3-speed transmission (plus reverse)

8N: 4-speed transmission (plus reverse)

The 8N’s four-speed transmission is one of the most significant improvements Henry Ford’s engineers made, and it’s a major reason why working 8N models command higher prices today. That extra gear makes a world of difference when you’re trying to match ground speed to the task at hand.

Why You Can Never Trust the Paint Color

Here’s a critical warning: ignore the paint entirely when identifying these tractors. I’ve seen 9N tractors painted in 8N colors, 8N tractors in all-gray 9N schemes, and even some creative souls who went with John Deere green “just because.”

The original color schemes were:

- 9N (1939-1942): Dark gray with red wheels

- 2N (1942-1947): Often dark gray overall due to wartime material restrictions

- 8N (1947-1952): Light gray with red trim

But after 80 years and countless backyard restorations, paint tells you absolutely nothing about what’s underneath. Stick with the pedals, lugs, and transmission—those don’t lie.

The Mechanical Face-Off: Why the 8N Commands a Premium Price

When you’re shopping for a Ford N tractor, you’ll quickly notice that running 8N models typically sell for $1,000 to $2,000 more than comparable 9N or 2N tractors. That price difference isn’t about collector value or rarity, it’s about real mechanical advantages that matter every single time you fire up the tractor.

1. The Transmission Advantage (The Single Biggest Dealbreaker)

The jump from the 9N’s 3-speed to the 8N’s 4-speed transmission represents one of the most significant improvements Ford made to the N-series tractors.

The 9N’s 3-Speed Problem:

The original 3-speed transmission was geared with wide spacing between each gear. First gear moved too fast for precision work like rototilling or operating a sickle bar mower. Third gear was too slow for efficient road travel but too fast for most field work. You constantly found yourself wishing for something in between.

I learned this the hard way trying to bush hog a pasture with a 9N. In second gear, I was moving too fast and scalping high spots. In first gear, I was crawling so slowly that the job took twice as long as it should have. The tractor wasn’t wrong, the transmission just didn’t give me the sweet spot I needed.

The 8N’s 4-Speed Solution:

Ford’s engineers didn’t just add a random fourth gear—they completely redesigned the transmission’s gear ratios to create what farmers call the “Sherman Tank” of tractor transmissions. The 4-speed gives you:

- A useful low gear for heavy pulling and slow-speed implements

- Two excellent middle gears for most field work

- A higher top gear for road travel (up to 12-13 mph vs. the 9N’s 10 mph)

That fourth gear transforms the tractor from a compromise machine into a truly versatile utility tractor. You can pull a loaded wagon down the road at a respectable pace, then drop into second gear and mow your pastures at the perfect height and speed.

2. Hydraulics: Draft Control vs. Position Control (The Feature Nobody Explains Clearly)

This is where most articles lose people in technical jargon, but it’s actually simple once you understand what these systems do in the real world.

9N and 2N (Draft Control):

The original Ford-Ferguson hydraulic system used draft control, which was specifically designed for plowing. The system senses resistance (draft) on the implement and automatically adjusts depth. When the plow hits hard ground, the hydraulics lift slightly to maintain consistent draft load. When it hits soft ground, the implement drops deeper.

This works brilliantly for plowing, exactly what it was designed to do in 1939. But here’s the problem: draft control is essentially “all the way up” or “all the way down” positioning. You can’t easily hold a bush hog, box blade, or finish mower at a consistent 4-inch cutting height. The implement either wants to float up or dig in based on ground resistance.

8N (Position Control):

The later 8N models introduced position control hydraulics, which changed everything for non-plowing tasks. Position control lets you set the implement at any specific height, and the hydraulic system holds it there regardless of ground conditions.

Want to grade a driveway? Set the box blade at exactly 2 inches depth and the hydraulics maintain that position. Need to mow at a consistent 3-inch height? Lock it in and go. This single feature makes the 8N dramatically more versatile for the kind of work most small farm owners actually do today, which is a lot more mowing and grading than plowing.

3. Engine and Distributor: The Mechanic’s Nightmare vs. The Easy Fix

All three N-series tractors share the same basic overhead valve engine design a 120 cubic inch, 4-cylinder powerplant producing around 23-28 horsepower depending on the year. But the distributor location changed dramatically, and it matters more than you’d think.

Front-Mount Distributor (9N, 2N, and Early 8N):

The original design placed the distributor at the front of the engine, directly in front of the radiator. To set the points or replace the distributor cap, you either need to:

- Remove the radiator (30-45 minute job)

- Work blind with a mirror and incredible patience

- Pull the distributor out and set the points on a workbench

Old-time mechanics call this the “distributor from hell,” and they’re not exaggerating. A 10-minute tune-up on a modern tractor becomes a frustrating hour-long ordeal.

Side-Mount Distributor (Late 1950-1952 8N):

Starting in late 1950, Ford moved the distributor to the side of the engine, similar to a modern car. Suddenly, setting points, changing the cap, and basic tune-ups became reasonable tasks you could do without disassembling half the tractor.

If you’re buying an 8N, check the serial number. Models built after approximately serial number 290,000 have the side-mount distributor—a significant advantage if you plan to do your own maintenance.

4. Chassis and Structural Improvements

The differences here are more subtle but still matter for long-term durability:

Front Radius Arms:

- 9N: I-beam construction

- 2N and 8N: Tubular construction (stronger and less prone to bending under heavy loader work)

Rear Wheel Hubs:

- 9N: Flat hub design

- 8N: Dished hub design (distributes stress better, particularly important if you’re running a rear-mounted implement or heavy rear tires)

These aren’t make or break differences for most users, but they represent Ford’s continuous improvement philosophy. Each change addressed real-world failures and farmer feedback.

| Related: Ford 8N Specs: PTO Horsepower, Value, and Uses

Understanding the 2N: The Wartime Tractor That Confuses Everyone

Here’s where things get really confusing, because many sellers don’t understand what a 2N actually is. You’ll see “9N” listings that are actually 2N tractors, and vice versa. Let’s clear this up once and for all.

What the 2N Actually Is

The Ford 2N (built from 1942-1947) is mechanically identical to the 9N in almost every way same 3-speed transmission, same draft control hydraulics, same split-brake design. The designation change from “9N” to “2N” in 1942 was primarily about wartime material restrictions and manufacturing changes, not mechanical improvements.

Key 2N Characteristics:

Due to World War II restrictions on strategic materials:

- Many early 2N tractors came with steel wheels instead of rubber tires (rubber was rationed)

- Some 2N models used magneto ignition instead of battery ignition (electrical components were in short supply)

- Starters were often deleted from 2N tractors (you hand-cranked them)

- Paint quality was generally lower due to material shortages

The Serial Number Trap That Fools Everyone

Here’s the real problem: both 9N and 2N tractors have serial numbers that start with “9N.”

The serial number sequence looks like this:

- 9N 1 through 9N 99,002: These are actual 9N tractors (1939-1942)

- 9N 99,003 through 9N 296,000: These are actually 2N tractors (1942-1947)

This numbering system has created 80 years of registration confusion, insurance headaches, and misleading sales listings. When someone shows you a “9N” with a serial number above 99,002, you’re looking at a 2N.

Why It Matters When Buying

The 2N is functionally a 9N with wartime compromises. If you’re buying a 2N today, verify:

- Has it been converted back to rubber tires? (Most have been)

- Does it have a working 6-volt electrical system? (Many have been upgraded to 12-volt)

- Is the starter functional? (Often added back after the war)

A fully restored 2N with modern upgrades is functionally identical to a 9N. Just don’t pay a premium for someone calling it a “rare wartime model” when it’s really just a 9N built during a difficult period.

The “Frankenstein” Factor: What 80 Years of Parts Swapping Means for Buyers

Here’s something most tractor guides won’t tell you: a significant percentage of N-series tractors you’ll encounter today are hybrids. After eight decades of farmers fixing things with whatever parts they had available, many of these tractors are combinations of multiple models.

Common Frankenstein Configurations

8N Engine in a 9N Chassis:

This is probably the most common swap. The 8N engine produces slightly more horsepower (around 27-28 hp vs. 23-24 hp) and often has the preferred side-mount distributor. Farmers would drop an 8N engine into an older 9N or 2N chassis, creating a more powerful version of the earlier tractor.

8N Running Boards on a 9N:

The 9N originally came without running boards (those step platforms on either side). When 8N running boards became available, many owners retrofitted them onto older 9N tractors for safety and convenience.

Transmission Upgrades:

Some ambitious owners have installed 8N 4-speed transmissions into 9N chassis. This is a more complex swap requiring matching clutch components, but it transforms the tractor’s usability.

12-Volt Electrical Conversions:

Nearly every N Series tractor you’ll find has been converted from the original 6-volt system to a more reliable 12-volt system. This is universally considered an improvement unless you’re doing a museum-quality restoration.

How to Verify What You’re Actually Buying

Don’t rely solely on the seller’s word or even the serial number plate. Here’s how to verify:

- Check Engine Casting Numbers: The engine block has casting numbers that tell you what it actually is, not what the serial number plate says.

- Match Serial Number Ranges:

- 9N: Serial numbers 9N 1 to 9N 99,002

- 2N: Serial numbers 9N 99,003 to 9N 296,000

- 8N: Serial numbers 8N 1 to 8N 524,076

- Look for Mismatched Features: If the serial plate says “9N” but you see 8-lug rear wheels and both brakes on the right side, you’ve got a hybrid or someone swapped the serial plate.

- Don’t Panic About Hybrids: A well-done parts swap can actually improve the tractor. An 8N engine in a 9N chassis might be better than either original configuration. Just make sure you’re paying for what you’re actually getting, not for what the seller thinks they have.

Modern Usability Guide: Which N-Series Tractor Matches Your Actual Needs?

Let’s get practical. You’re not buying this tractor to display in a museum, you’ve got work to do. Here’s how each model performs for common small farm and homestead tasks.

Bush Hogging and Pasture Mowing

Winner: Ford 8N

The position control hydraulics make all the difference here. Maintaining consistent cutting height across uneven terrain is dramatically easier with the 8N. The 4-speed transmission also gives you the perfect ground speed for clean cuts without bogging down in heavy growth.

I’ve mowed with both models, and the difference is night and day. With a 9N, you’re constantly fighting the draft control system, which wants to lift the mower deck over every bump or drop it into every depression. The 8N just holds the height you set and goes.

Plowing and Discing

Tie: Both Excel

This is what the 9N was originally designed to do, and it does it beautifully. The draft control system actually provides an advantage here, automatically compensating for varying soil conditions. The 8N handles plowing equally well with position control.

If plowing is your primary use, save money and get the 9N or 2N. You won’t miss the features the 8N offers.

Grading Driveways and Leveling

Winner: Ford 8N

Position control is essential for grading work. You need to hold that box blade or rear scraper at an exact depth, and the 8N’s hydraulics do this effortlessly. Fighting with draft control on a 9N while trying to grade is an exercise in frustration.

Snow Plowing

Winner: Ford 8N

The improved reverse gearing and better braking system (both pedals on the right side that can be locked together) make the 8N safer and more controllable for snow removal work. The 4-speed transmission also gives you better gear options for pushing heavy, wet snow.

Pulling Wagons and Road Travel

Winner: Ford 8N

That higher top gear (around 12-13 mph vs. 10 mph) makes a real difference when you’re hauling firewood, hay, or supplies. It’s still not fast by modern standards, but 20-30% faster adds up over a day’s work.

Parades, Shows, and Collectibility

Slight Edge: Ford 9N

If you’re looking for a restoration project or a parade tractor, original 9N models in good condition are somewhat rarer than 8N tractors (Ford produced many more 8N models during its longer production run). A numbers-matching, unmodified 9N can be more collectible.

However, the 8N is often more impressive to show audiences because it represents the culmination of the N-series design improvements.

Loader Work

Winner: Ford 8N (Barely)

Neither tractor was designed for loader work, but modern owners often add front-end loaders. The 8N’s stronger tubular front radius arms and slightly better weight distribution give it a minor edge. That said, both tractors are light for serious loader work—a modern compact tractor significantly outperforms either model in this category.

Critical Safety Warning: The Live PTO Issue You Must Understand

Before you buy any Ford N-series tractor, you need to understand a serious safety limitation that affects all three models: none of them have a live PTO (power take-off).

What This Means in Plain English

On modern tractors, the PTO has its own clutch independent from the transmission. You can stop the tractor while keeping the implement running, or you can keep the tractor moving while stopping the implement.

On Ford N tractors, the PTO is directly connected to the transmission. When you push in the clutch to stop or shift, the PTO also stops. When you let the clutch out, the PTO spins. This creates a dangerous situation with rotary implements like mowers and bush hogs.

The Actual Danger

Picture this scenario: You’re bush hogging with your 9N or 8N, moving along at a good pace. You see an obstacle ahead and push in the clutch to stop. The tractor clutch disengages, but that 5-foot rotary cutter behind you has tremendous rotational momentum.

Instead of stopping, those spinning blades actually push the tractor forward through the clutch. The tractor can roll several feet—potentially into a fence, ditch, or other obstacle—before the momentum dissipates. I’ve personally witnessed a Ford 8N get pushed through a barbed wire fence this way, causing several hundred dollars in damage and nearly injuring the operator.

The Mandatory Solution: Overrunning Coupler

Never operate a rotary mower or bush hog without an overrunning coupler (ORC) installed on the PTO shaft.

An overrunning coupler is a mechanical device that allows the implement to spin faster than the PTO without back-driving the tractor. When you push in the clutch, the ORC lets the mower deck coast down safely without pushing the tractor forward.

These devices cost $50-150 and are absolutely mandatory for safe operation. Most modern implements come with them built-in, but if you’re using vintage equipment or aftermarket implements, verify the ORC is present before operation.

Other Safety Considerations

Roll-Over Protection: None of the Ford N tractors came with ROPS (Roll-Over Protection Structure) from the factory. Modern retro-fit ROPS kits are available and strongly recommended, especially if you’re working on slopes or hillsides.

Braking on Hills: The mechanical brakes on all N-series tractors are adequate but not impressive by modern standards. Respect their limitations, especially when pulling loaded implements on steep grades.

Steering Clearance: These narrow front-end tractors can tip more easily than modern wide-front designs. Use caution on side slopes and when turning sharply with heavy implements.

Buying Guide: What to Check Before Handing Over Cash

You’ve found a Ford N tractor for sale. Before you pull out your wallet, here’s what you need to inspect.

Critical Inspection Points

1. Cracked Engine Block

The most expensive problem on these tractors: a cracked block. The most common location is behind the carburetor on the right side of the engine. Look for:

- Visible cracks in the casting

- Evidence of stop-leak sealant or epoxy repairs

- Coolant weeping from the block

- Oil mixed with coolant

A cracked block doesn’t automatically mean walk away—many have been professionally repaired with welding or epoxy—but it absolutely affects the price.

2. Hydraulic Lift Cover Cracks

The rear hydraulic lift cover is prone to cracking if water got into the system and froze. Check:

- The large cast housing behind the seat

- Any signs of previous welding repairs

- Hydraulic fluid leaks

A cracked lift cover can be welded or replaced, but it’s a several-hundred-dollar repair.

3. Transmission Condition

With the engine running:

- Shift through all gears (should engage smoothly with minimal grinding)

- Check for jumping out of gear under load

- Listen for excessive whining or grinding

- Verify reverse works properly

Transmission repairs on these tractors are labor-intensive but parts are readily available.

4. Rear End and Final Drives

- Check for oil leaks around the rear axle seals

- Listen for unusual noises from the rear differential

- Verify both brakes work (even if they need adjustment)

5. Electrical System

Most have been converted to 12-volt. Verify:

- Lights work (if equipped)

- Starter engages reliably

- Generator/alternator charges properly

- No amateur wiring that could cause fires

6. Tire Condition

Good rear tires for these tractors cost $400-800 per pair. Factor this into your offer if the tires are worn, dry-rotted, or weather-checked.

7. Evidence of Parts Swapping

Use the identification methods from earlier in this article to verify the tractor is actually what the seller claims. Mismatched components aren’t necessarily bad, but you should pay for what you’re actually getting.

2026 Market Value Estimates

Prices vary significantly by region, condition, and local demand, but here are realistic ranges for the current market:

Project/Non-Running Condition:

- 9N/2N: $500 – $1,200

- 8N: $800 – $1,500

Running Condition (Needs Work):

- 9N/2N: $1,500 – $2,500

- 8N: $2,200 – $3,500

Good Working Condition:

- 9N/2N: $2,500 – $4,000

- 8N: $3,500 – $5,500

Excellent Restored Condition:

- 9N/2N: $4,000 – $7,000

- 8N: $5,500 – $9,000

Museum-Quality Restoration:

- 9N/2N: $7,000 – $12,000

- 8N: $9,000 – $15,000

Red Flags That Should Lower Your Offer

- Recent paint job that looks suspiciously good (possibly hiding problems)

- Seller can’t produce the serial number or it doesn’t match the model claimed

- Evidence of amateur welding repairs on structural components

- Strong smell of burning oil when running

- Excessive smoke (blue = burning oil, white = coolant)

- Modifications that permanently damage originality (if that matters to you)

Green Flags That Justify Paying More

- Side-mount distributor on 8N models (1950-1952)

- Professional 12-volt conversion with quality components

- Recent hydraulic system rebuild with documentation

- New tires with good tread

- Complete set of original implements (plow, disc, etc.)

- Verified low hours or single-owner history

Conclusion: Making the Right Choice for Your Needs

After eight decades, the Ford N-series tractors remain some of the most practical, affordable, and maintainable vintage tractors you can own. But is the Ford 8N worth the typical $1,000-$2,000 premium over a comparable 9N or 2N?

- Primarily need to plow gardens or food plots

- Want the most affordable entry into vintage tractor ownership

- Value originality and early production history

- Don’t mind working around the 3-speed transmission limitations

- Plan to do mostly pulling work (wagons, trailers, etc.)

- Need to mow pastures or maintain grass regularly

- Want to do grading, leveling, or precision depth work

- Value the improved transmission and position control hydraulics

- Prefer easier maintenance (especially if you can find a side-mount distributor model)

- Want the most versatile N-series tractor for varied farm tasks

The honest truth? For most small farm and homestead owners doing typical 21st-century tractor work: mowing, grading, light hauling, the 8N’s improvements justify every penny of the price premium. The 4-speed transmission and position control hydraulics transform the tractor from a specialized plowing machine into a genuinely versatile utility tractor.

But if you’re on a tight budget and your primary needs involve pulling implements or you’re learning on your first tractor, a good 9N or 2N will serve you faithfully for decades. Parts are identical for 90% of components, and the thriving Ford tractor community means help is always available.

Whichever model you choose, you’re getting a piece of American agricultural history that helped save small farms during and after World War II. With reasonable care and maintenance, your Ford N tractor will likely still be working long after modern compact tractors have been scrapped.

Now get out there, use the identification tips from this guide, and find the right N-Series tractor for your needs. Just remember to check those brake pedals before you make your offer.

Frequently Asked Questions

Can I put an 8N transmission in a 9N tractor?

Yes, but it’s a complex swap requiring matched components. You’ll need the 8N transmission, bell housing, clutch assembly, and potentially the PTO shaft. The hydraulic lift system may also need modification. Most mechanics recommend buying an 8N rather than converting a 9N, unless you already own a 9N with a blown transmission and can find a good 8N transmission affordably.

What is the Sherman Step-Up transmission, and should I look for one?

The Sherman Step-Up is an aftermarket overdrive transmission that was popular in the 1950s-1960s. It bolted between the tractor transmission and the rear end, providing higher road speeds (up to 16-18 mph). These are now quite rare and collectible. If you find one installed, it’s a bonus for road travel, but verify it’s still functional—rebuilding them is difficult due to parts scarcity.

Do 9N parts fit an 8N tractor? What about parts interchangeability?

Most parts interchange between all three N-series models. The major exceptions are:

- Transmissions (3-speed vs. 4-speed)

- Hydraulic lift systems (draft vs. position control)

- Rear wheels and hubs (6-lug vs. 8-lug)

- Some hood and sheet metal pieces

Engine parts, front axle components, steering parts, and most tin work are interchangeable. This excellent parts compatibility is one reason these tractors remain popular—you can often use 9N parts to repair an 8N and vice versa.

Is the lack of live PTO a deal breaker for modern use?

Not if you use proper safety equipment. An overrunning coupler eliminates the main danger. Many owners successfully use these tractors for decades with rotary cutters and bush hogs by following proper safety protocols. However, if you’re running a PTO-intensive operation (hay production with multiple implements, serious commercial mowing), a newer tractor with live PTO and live hydraulics will be more efficient and safer.

Which N-Series tractor is best for a beginner?

The 8N is the most forgiving for beginners due to the 4-speed transmission giving you more options to match conditions, and the position control hydraulics being more intuitive. However, a 9N or 2N in good mechanical condition with patient instruction can teach the same skills. Start with whichever model you can find in the best condition within your budget. The learning curve is similar for all three—these are simple tractors by design.

Should I avoid a tractor that’s been converted to 12-volt?

Absolutely not! The 12-volt conversion is one of the best improvements you can make to an N-series tractor. The original 6-volt systems are notoriously unreliable by modern standards, especially in cold weather. A quality 12-volt conversion improves starting, lighting, and overall electrical reliability. Only avoid it if you’re doing a museum-quality restoration where originality matters.