Choosing between a skid steer and a compact track loader (CTL) is one of the most significant decisions a business owner in construction, landscaping, or agriculture can make. While beginners often call these machines “tractors,” they are technically specialized compact loaders designed for maximum agility and power.

This guide breaks down the technical specifications, operational advantages, and cost analyses to help you invest in the right machine for your fleet.

Key Takeaways

- Terrain Specialization: Skid steers are optimized for hard, flat surfaces like concrete or asphalt, while track loaders (CTLs) are essential for stability on soft, muddy, or uneven terrain.

- Cost and Maintenance: Skid steers offer lower upfront prices and significantly cheaper maintenance costs because tires are less expensive to replace than complex track systems.

- Maneuverability vs. Traction: Skid steers excel in tight spaces with their ability to turn in place, whereas track loaders provide superior traction and “flotation” for heavy pushing and grading.

- Operational Efficiency: Compact wheel loaders generally provide longer service lives and better fuel efficiency than skid steers, leading to a lower total cost of ownership per hour.

- Job Site Versatility: Both machines utilize universal quick-couplers to operate over 100 different attachments, allowing one machine to function as a loader, excavator, or snow blower.

Introduction: The Power of Compact Loaders

Both skid steers and compact track loaders are incredibly versatile job site staples. Their primary strength lies in their ability to handle a vast array of tasks using universal quick-couplers, which allow operators to switch between buckets, pallet forks, augers, snowblowers, and even pavement millers in under a minute.

Despite their visual similarities, a compact body with a front-mounted attachment, they differ fundamentally in how they traverse the ground and manage weight. Understanding these differences is the key to maximizing your productivity.

Key Differences: Wheels vs. Tracks

The core of the skid steer vs track loader debate is the undercarriage.

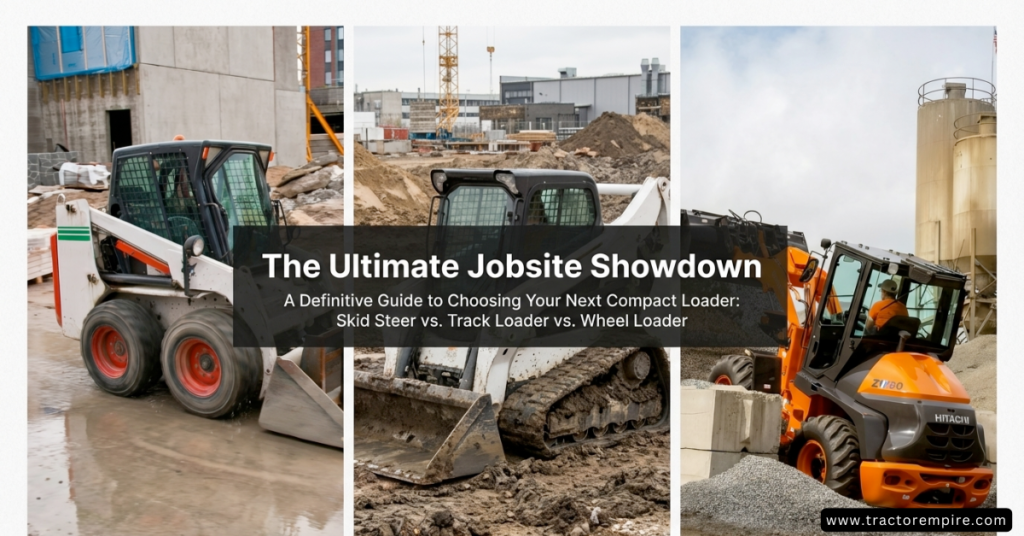

- Skid Steers: These feature four wheels and a rigid frame. They steer by braking or reversing one side of the machine while the other side continues to move, causing the tires to “skid” across the surface to turn.

- Compact Track Loaders (CTLs): These run on two parallel high-flotation rubber tracks. Instead of weight being concentrated on four tire points, tracks distribute the machine’s weight over a much larger surface area, reducing ground pressure by up to 60%.

Performance Breakdown: Speed, Power, and Agility

Maneuverability and Maneuvering Skid steers have a definitive maneuverability advantage in tight areas. They can turn on a dime, rotating 360 degrees within their own footprint. CTLs have similar turning capabilities but are generally larger and slower during turns, often requiring more space to maneuver effectively.

Travel Speed If your job requires moving material over long distances, speed is a factor. Skid steers are faster, typically reaching speeds of 7–12 mph, whereas CTLs are slightly slower at 6–10 mph. Turning and cycling back and forth is also notably faster in a wheeled machine.

Stability and Lifting Capacity CTLs offer superior stability due to a lower center of gravity and a larger footprint. This increased stability allows them to have a higher Rated Operating Capacity (ROC) and more tipping load compared to a similarly sized skid steer, making them better for heavy-duty pushing, grading, and dozing.

Terrain Suitability: Where Do You Work?

Your typical job site environment is the biggest factor in the CTL vs skid steer terrain comparison.

- The Case for Skid Steers (Hard Surfaces): Skid steers excel on concrete, asphalt, and packed gravel. Tires are more durable on these abrasive surfaces; in contrast, driving a CTL on hard ground can cause serious damage to the tracks in just a day or two.

- The Case for CTLs (Soft/Uneven Ground): CTLs are essential for mud, snow, sand, and slopes. Their low ground pressure provides “flotation,” allowing them to stay on top of soft surfaces where a wheeled skid steer would likely sink and get stuck.

Maintenance and Ownership Costs

Investing in these machines requires a clear look at skid steer maintenance costs versus CTL upkeep.

Initial Purchase and Rental Skid steers are the more cost-effective option upfront, typically costing 10% to 25% less than a CTL of the same size. For example, a medium-sized skid steer may start around $66,000, while its tracked counterpart could be $85,000.

Wear Items and Upkeep

- Tires vs. Tracks: A set of skid steer tires is significantly cheaper, ranging from $800 to $1,500. CTL rubber tracks are a major expense, costing between $2,500 and $5,000+ per set.

- Undercarriage: CTLs have complex undercarriages with rollers, idlers, and sprockets that require frequent cleaning and costly annual maintenance. Skid steers have a much simpler wheel system that is easier to inspect and clean.

- Fuel and Durability: Skid steers are generally more fuel-efficient because tracks generate high friction, which strains the engine and increases fuel consumption. However, articulated compact wheel loaders often have a longer design life (6,000–8,000 hours) compared to traditional skid steers (5,000 hours).

Operator Comfort and Modern Technology

In 2026, modern machines are re-engineered to prioritize operator comfort and precision.

- Ride Quality: CTLs provide a much smoother ride. Tracks bridge over small bumps and furrows that would cause a wheeled skid steer to bounce—a phenomenon known as “catwalking”—which can lead to material loss from the bucket.

- Visibility: Skid steers offer great forward visibility but can have poor views to the sides and back. Higher-seated articulated loaders or modern CTLs with 360-degree glass cabs allow for easier spotting of attachments at full height.

- Smart Technology: Advanced systems like John Deere’s SmartGrade™ and Cat’s Smart Attachments are often exclusive to CTLs. These 3D grading systems automate precision tasks, reducing labor costs and reworks.

Site Cleanup and Finish Work

The aftermath of a job is just as important as the execution. Skid steers are preferred for quick cleanup on hard, developed surfaces in urban areas. However, their wheels can easily tear up turf and leave deep ruts in soil. CTLs are much gentler on grass and finished landscaping, making them the preferred choice for residential projects where minimizing ground disturbance is a priority.

Conclusion: Making the Right Choice

The final decision comes down to your budget and where you spend most of your time working.

Frequently Asked Questions (FAQ)

Q: What is the difference between ROC and tipping load?

A: Rated Operating Capacity (ROC) is the safe working limit—usually 35% to 50% of the tipping load. Tipping load is the point where the machine becomes unstable and could tip forward.

Q: Can I use tracks on a wheeled skid steer?

A: You can add over-the-tire tracks for temporary traction, but they do not provide the same low ground pressure or flotation as a dedicated CTL.

Q: Which is better for snow removal?

A: Skid steers are often preferred for their speed and grip on hard surfaces. However, CTLs with bar-style treads offer excellent stability for stockpiling and loading snow.

Q: How many hours do these machines last?

A: Skid steers typically have a useful life of about 5,000 hours, whereas some compact wheel loaders can last between 6,000 and 8,000 hours.