I’ve watched too many new farmers make the same mistake: they walk into a dealership thinking horsepower is everything, and they walk out with either a gutless machine that can’t handle their workload or an oversized beast that compacts their soil and drains their bank account.

Here’s the truth, the best tractor for small farm operations isn’t about raw power. It’s about matching your specific needs to the right equipment.

Whether you’re managing 3 acres of market garden rows or 40 acres of pasture for livestock, this guide will help you choose the perfect tractor for your operation.

Key Takeaways

- Small farms (1–50 acres) require different tractor specifications based on primary tasks

- Under-buying creates safety issues and engine strain; over-buying wastes capital and damages soil

- The “best” tractor balances horsepower, transmission type, lift capacity, and dealer support

- Total cost of ownership often matters more than purchase price

The scope we’re covering: This guide focuses on properties between 1 and 50 acres, the sweet spot where choosing the right compact tractor makes the difference between efficient farm management and constant frustration. We’re not listing every model available. Instead, I’m matching proven machines to your specific farming goals so you can make a confident, informed decision.

- The Decision Framework: 4 Pillars of Choosing the Right Tractor

- Top Tractor Picks by Farm Profile: Finding Your Perfect Match

- The System Approach: Building Your Tractor's Capability with Attachments

- Financials: New vs. Used & Total Cost of Ownership

- Maintenance & Ownership Reality: What Nobody Tells You at the Dealership

- Comparison Table: At-a-Glance Specs for the Best Tractors for Small Farms

- Conclusion: Making the Best Choice for Your Small Farm

- Frequently Asked Questions

The Decision Framework: 4 Pillars of Choosing the Right Tractor

Most tractor reviews jump straight to model comparisons. That’s backwards. You need to understand what actually matters before you can evaluate which compact utility tractor fits your small farm.

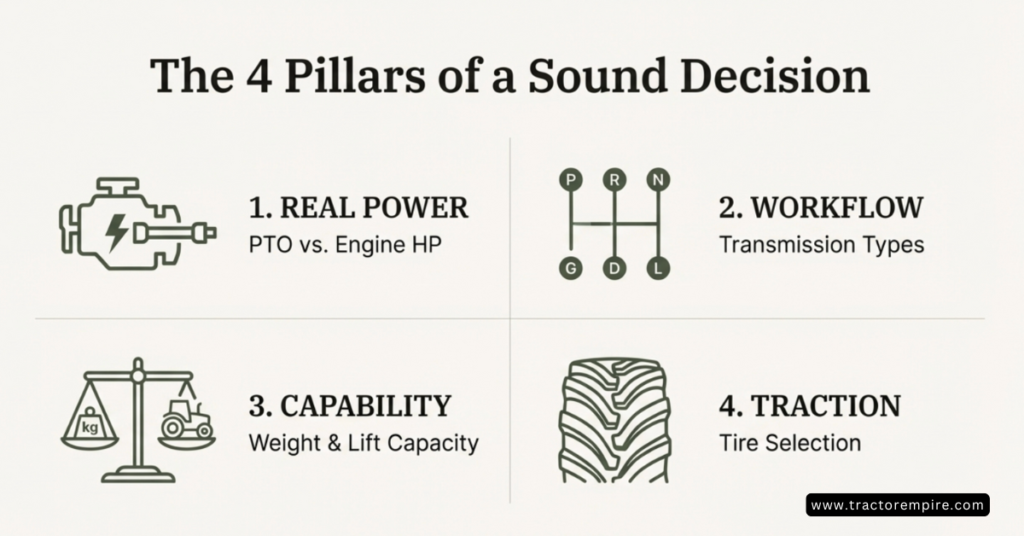

1: Horsepower vs. PTO Horsepower—Understanding Real Power

Here’s what the dealership won’t always explain clearly: engine horsepower and PTO horsepower are different animals.

Engine horsepower moves your tractor across the field. PTO (Power Take-Off) horsepower runs your implements, your mower, tiller, post hole digger, and other attachments. This distinction matters because you lose power in transmission.

With hydrostatic transmissions (common in compact tractors), you typically lose 15–20% of your engine’s power by the time it reaches the PTO shaft. So that 25 HP tractor? You’re getting roughly 20–21 HP to actually run your equipment.

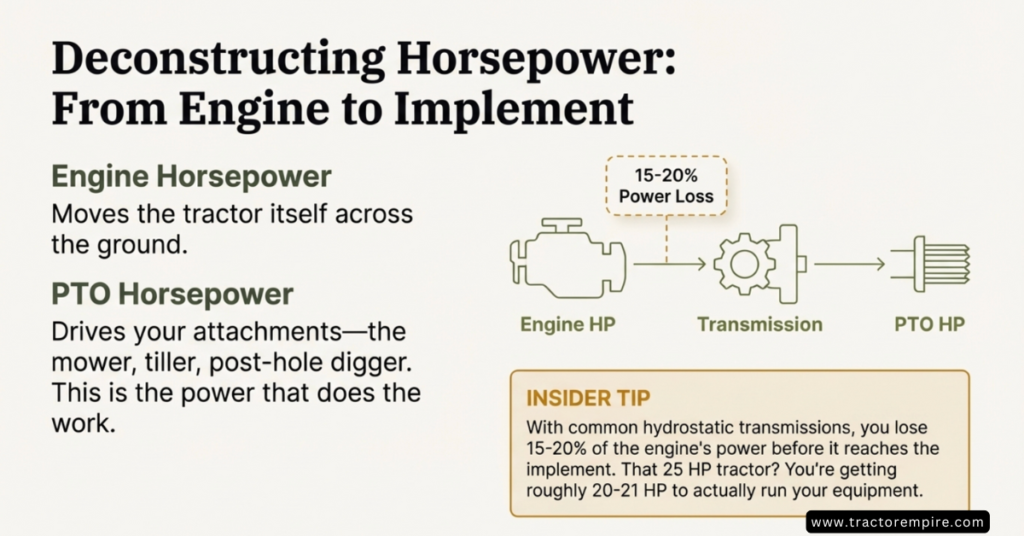

Why this matters for your small farm: If you’re planning to run a 5-foot rotary tiller or a heavy-duty brush hog, you need sufficient PTO horsepower not just impressive engine specs on the brochure. A kubota or john deere compact tractor rated at 25 HP will handle most implements for hobby farms, but pushing into the 35–45 HP range gives you headroom for heavy-duty tasks without straining the engine.

2: Transmission Types—The Make or Break Decision

Your transmission choice affects everything from loader work efficiency to fuel consumption. Here are your two main options:

Hydrostatic (HST):

- Best for: Loader work, mowing, frequent direction changes, and beginners

- How it works: Foot pedal control, press forward to go, press backward to reverse. Think of it like an automatic car.

- Advantages: Unbeatable convenience, smooth operation, no clutching needed

- Trade-offs: Slightly lower fuel efficiency, less power transfer to ground engagement

If you’re constantly switching between moving dirt piles, mowing pastures, and moving hay bales around, hydrostatic is your friend. The consistent performance and ease of use justify the small power loss for most small farm operations.

Gear/Shuttle Shift:

- Best for: Long, straight tillage rows and maximizing available power

- How it works: Manual gear selection with a shuttle lever for forward/reverse

- Advantages: Better power delivery, superior fuel economy, excellent for ground engagement

- Trade-offs: Learning curve, more fatigue during loader work

Market gardeners running a tiller down 100-foot beds will appreciate the efficiency of gear transmissions. You’re trading convenience for productivity in specific applications.

3: Weight & Lift Capacity—The Hidden Specs That Matter

This is where manufacturers get creative with their marketing. You’ll see impressive lift capacity numbers that don’t tell the full story.

Understanding the numbers:

- “Lift capacity at pivot pin”: The maximum weight the loader can lift when the load is positioned right against the tractor (unrealistic for actual work)

- “Lift capacity at 24 inches”: More realistic measurement, this is what you can actually lift with a loaded bucket extended forward

A heavier tractor is safer for loader work. Period. When you’re lifting 800 pounds of gravel or manure, you want ballast to prevent the rear wheels from lifting off the ground. This is why brands like john deere and kubota often spec their compact utility tractors with optional loaded rear tires or bolt-on wheel weights.

Real-world guidance: For serious loader work (moving livestock feed, gravel, compost), look for tractors in the 2,500–3,500 pound operating weight range with loader lift capacity exceeding 1,200 pounds at full extension. Lighter subcompact models work fine for landscaping and light property maintenance, but they’ll struggle and become unsafe when asked to do heavy lifting.

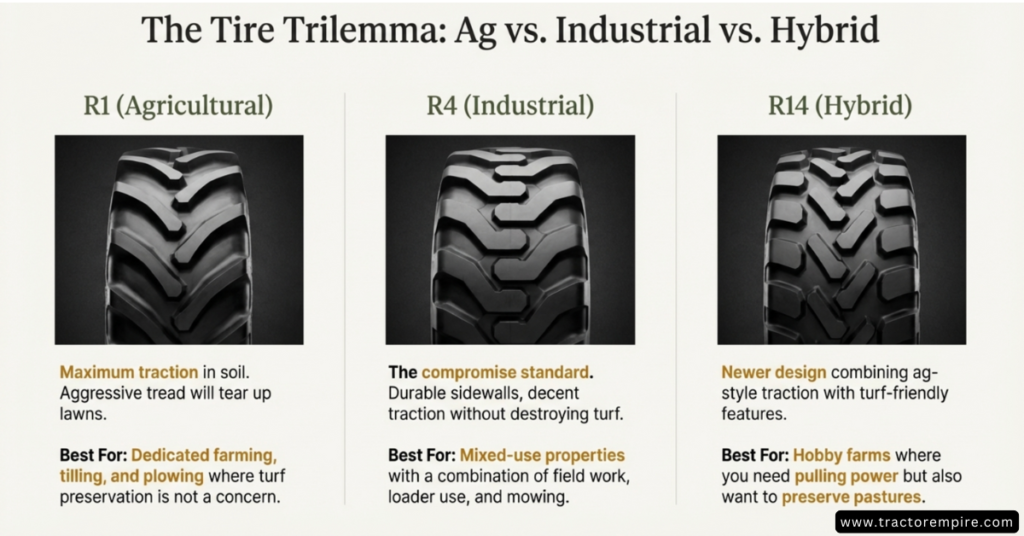

4: Tire Selection—More Than Just Tread

Most tractors for small farms come with one of three tire configurations, and your choice impacts everything from traction to turf damage.

R1 (Agricultural):

- Maximum traction in soil

- Aggressive tread tears up lawns

- Best for: Dedicated farming applications where grass preservation doesn’t matter

R4 (Industrial):

- The compromise standard for compact tractors

- Durable sidewalls resist punctures

- Decent traction without destroying turf

- Best for: Mixed-use properties with both farming and landscaping needs

R14 (Hybrid):

- Newer tire design combining ag traction with turf protection

- Growing in popularity for hobby farms

- Best for: Properties where you need pulling power for implements but also want to preserve pastures and lawns

My take: Unless you’re exclusively row-cropping or running a market garden, R4 industrial tires give you the best balance of power and versatility. They handle snow removal in winter, mowing in summer, and loader work year-round without chewing up your property.

Top Tractor Picks by Farm Profile: Finding Your Perfect Match

Here’s where we match specific tractors to real farming scenarios. Instead of a generic “best compact tractor” list, I’m categorizing by your primary task because a tractor that excels at loader work might frustrate you in the vegetable rows.

A. Best All-Rounder for Mixed-Use Small Farms (5–10 Acres)

Winner: Kubota L2501 / L Series Tractor

The kubota l2501 sits in the perfect sweet spot for small farm versatility. At 24.8 HP, it stays under the 25 HP threshold that triggers emissions equipment (no DPF regeneration headaches), yet delivers enough muscle for most small tractor tasks.

Why it wins:

- Clean-running engine with no diesel particulate filter complications

- Exceptional dealer network—you’ll find kubota service almost anywhere

- Proven durability with high resale value

- Available in both 2WD and four-wheel drive configurations

- Handles a 5–6 foot rotary cutter, box blade, and front end loader simultaneously

This is the tractor that will serve you whether you’re maintaining pastures, managing livestock areas, or doing seasonal property maintenance. It won’t break any performance records, but it won’t break down either.

Runner-Up: John Deere 3025E

The john deere 3025e brings premium ergonomics and arguably the smoothest loader operation in its class. The 3 Series tractor line from Deere focuses on operator comfort, if you’re spending 4+ hours in the seat regularly, you’ll appreciate the refined controls. Trade-off? You’ll pay 15–20% more than comparable models for that green paint and nearby dealer support.

B. Best Compact Tractor for Market Gardens & Row Crops

Winner: Massey Ferguson 1800 M Series

Market gardeners need different things than livestock farmers. You want a tractor with a heavy frame for ground engagement, precise implement control, and the ability to navigate tight spaces between crop beds.

The Massey Ferguson 1800 M (formerly part of their 2 Series lineup) delivers a robust chassis that keeps tillage implements stable and consistent. The draft control system on the 3-point hitch is more responsive than most competitors in the 25–35 HP range, which matters when you’re trying to maintain consistent tiller depth across varying soil conditions.

Why market gardeners choose it:

- Heavier frame weight improves traction for ground-engaging implements

- Superior draft control for tillage consistency

- Narrow front-end options for row crop work

- Available with agricultural R1 tires standard

Runner-Up: Farmall (Case IH) Compact A Series

If you prefer gear transmission for maximum power delivery during tillage, the Farmall compacts offer that option. They’re built tough, these tractors share DNA with Case IH’s larger agricultural equipment. The trade-off is a smaller dealer network in some regions and slightly less refined ergonomics compared to the top brands.

C. Best for Livestock Operations & Heavy Loader Work

Winner: Kioti CK2610 / CK3510

Here’s where value meets capability. Kioti tractors consistently deliver higher lift capacity and better loader specifications per dollar than their green and orange competitors.

The CK Series includes industrial-grade loaders with “Bobcat-style” quick attach buckets standard—not an expensive add-on. When you’re mucking out stalls, moving round hay bales, or hauling feed, you’ll cycle through different bucket types constantly. Quick-attach makes this effortless.

Specifications that matter for livestock work:

- Loader lift capacity: 1,500+ lbs at 24″ extension (CK3510)

- Standard SSQA (skid steer quick attach) bucket interface

- Heavier operating weight for stability

- Competitive pricing leaves budget for essential attachments

The kioti consideration: You won’t find as many kioti dealers as Kubota’s or John Deere’s dealer network, so verify service availability in your area before buying. But if you have good local support, these tractors punch well above their weight class for loader-intensive operations.

D. Best Subcompact for Small Acreage & Landscaping (1–3 Acres)

Winner: John Deere 1025R

For weekend property owners and landscape-focused operations under 3 acres, the 1025R has earned its reputation. The “AutoConnect” mid-mount mower deck is genuinely innovative you literally drive over it and it connects automatically. No wrestling with pins and belts.

The quick-park loader system is similarly convenient. Both features matter when you have limited time and multiple tasks to accomplish.

Best for:

- Properties where mowing is the primary task

- Owners who value convenience over maximum capability

- Operations requiring frequent attachment changes

- Tight spaces with limited maneuvering room

Trade-offs: You’re paying a premium for that convenience and John Deere brand. This is the most expensive tractor per horsepower in this guide.

Runner-Up: Kubota BX23S

If you need occasional backhoe work (fence post holes, small drainage trenches), the BX23S integrates a factory backhoe better than any competitor. The backhoe is specifically engineered for this chassis, not a bolt-on afterthought. For small acreage homesteaders planning to expand infrastructure, this versatility justifies the investment.

| Related: John Deere 1025R Specs, Features, Attachments & Buying Guide

E. Best Value: Maximum Features Per Dollar

Winner: TYM or Mahindra Compact Tractors

Let’s talk about the value brands that established dealers don’t always promote. TYM (formerly sold as Branson in some markets) and Mahindra both originate from solid manufacturing backgrounds and offer significantly more features in their base packages.

What you get that costs extra elsewhere:

- Rear hydraulic remotes (for grapples and other powered attachments)

- Higher loader lift capacity in comparable HP ranges

- Longer warranty coverage (often 5+ years powertrain)

- Loaded tires and wheel weights included

The honest trade-off: Dealer network density is lower. If your nearest TYM or Mahindra dealer is 90 minutes away, warranty service becomes a logistical hassle. But if you have good local support, you’ll get 80–90% of the capability of top brands for 60–70% of the price.

Who should consider value brands:

- Mechanically inclined owners comfortable with basic maintenance

- Buyers in areas with established value-brand dealerships

- Operations where upfront cost matters more than resale value

- Farms planning to expand their fleet affordably

The System Approach: Building Your Tractor’s Capability with Attachments

Your tractor is only as useful as the implements you can run with it. This is where many small farm operators under-plan and end up limited by compatibility issues or missing hydraulic connections.

The Front End Loader: Your Most Important Attachment

I’ll be direct: 99% of small farm tractor buyers should purchase the front end loader with their tractor as a factory package. Not later. Not as an afterthought. Now.

Why this matters:

- Factory loaders are engineered specifically for your tractor’s frame and hydraulics

- Package pricing saves $800–$1,500 compared to adding later

- Resale value stays higher with complete tractor/loader combinations

- Weight distribution and hydraulic routing are optimized from the factory

SSQA vs. Pin-On Buckets: This is non-negotiable for future versatility. Skid Steer Quick Attach (SSQA) buckets let you switch between standard buckets, grapple buckets, pallet forks, and bale spears in under 60 seconds. Pin-on buckets require hammering out pins and fighting with implement weight. Pay the $200–300 extra for SSQA compatibility upfront.

The 3-Point Hitch: Category Confusion and Compatibility

Most compact tractors come with Category 1 three-point hitches. Smaller subcompacts might use Category 0. This matters because implements are category-specific.

That used tiller you’re eyeing on Craigslist? Verify the category matches your tractor. Cat 1 implements won’t properly connect to Cat 0 hitches without adapters that compromise lifting geometry.

Quick Hitch Systems: These universal adapters let you connect implements in 30 seconds instead of 10 minutes of alignment struggles. Are they worth $250–350?

Absolutely yes, if you’re regularly switching between implements. Your back will thank you after the first month. If you only use 2–3 implements seasonally, standard pin connections work fine.

Rear Hydraulic Remotes: Planning for Future Needs

Rear remotes are auxiliary hydraulic ports mounted at the back of your tractor. They power cylinders on grapples, top-and-tilt buckets, rear blades, and other advanced attachments.

Here’s the planning issue: Adding rear remotes after purchase costs $800–$1,200 in parts and labor. Getting them factory-installed during your initial purchase? Often $400–600, or sometimes included in premium packages.

When you need them:

- Root grapples for land clearing

- Top-and-tilt capabilities on box blades

- Log splitters

- Some commercial mower decks

Many new buyers skip this option, then regret it 18 months later when they want to add a grapple. If there’s any chance you’ll expand your implement collection, add remotes now.

Financials: New vs. Used & Total Cost of Ownership

Let’s talk money realistically. The used tractor market has been absurd for the past few years, and it’s changed the math on new vs. used purchases.

The “0% Financing” Reality Check

Many manufacturers offer 0% financing on new tractors for 36–60 months. When you run the actual numbers against buying a 3–5 year old used tractor with cash, the new purchase often wins on total cost.

Example scenario:

- New Kubota L2501 with loader: $22,000 at 0% for 60 months

- Used 2019 L2501 with similar hours: $18,500 cash

Your monthly payment on the new tractor is $367. Over five years, you’ve paid exactly $22,000. That used tractor at $18,500 seems like a bargain—until you factor in:

- No warranty coverage (you’re absorbing repair costs)

- Potential for deferred maintenance issues

- Missing attachments or worn components

- Higher hours on engine and transmission

The $3,500 savings evaporates quickly if you need one hydraulic cylinder rebuild or a clutch replacement. New with 0% financing provides predictable costs and warranty protection.

Understanding Depreciation by Brand

Not all tractors hold value equally. This affects both resale and used purchase decisions.

Low depreciation (excellent resale value):

- Kubota: Typically retains 70–75% of value after 5 years

- John Deere: Similar retention, especially on popular models like the 3025E or 3 Series tractors

Moderate depreciation (good used values):

- New Holland, Massey Ferguson, Kioti: 60–65% retention

- These become attractive used purchases after 3–4 years

Higher initial depreciation (best second-hand opportunities):

- TYM, Mahindra, LS: 50–60% retention

- Excellent values for cash buyers who want newer equipment at significant discounts

Strategic insight: If you’re buying used, target the higher-depreciation brands for the best deals. If buying new and planning to upgrade in 5–7 years, stick with Kubota or Deere for better resale recovery.

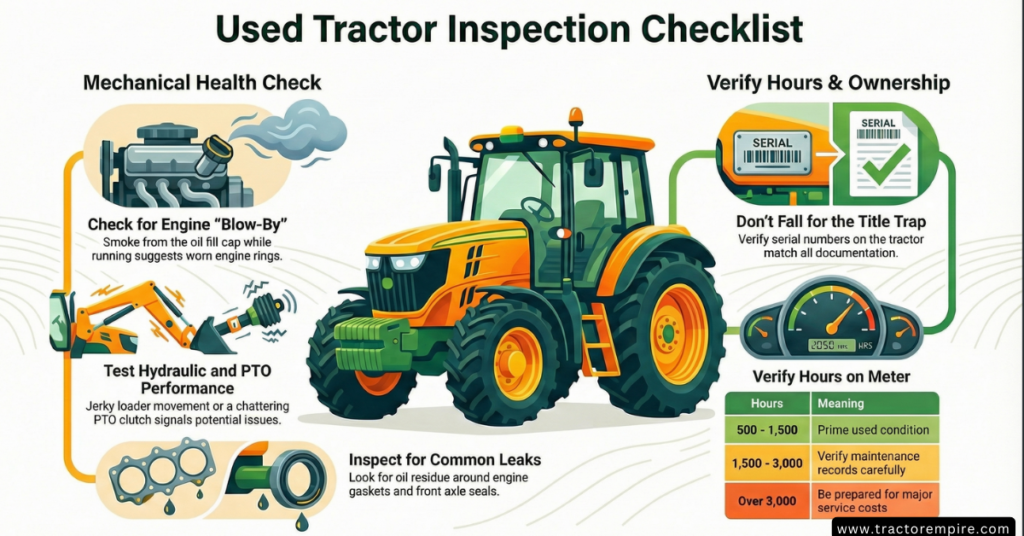

Used Tractor Inspection Checklist

If you’re shopping used tractors, verify these critical points before money changes hands:

Engine health:

- Remove oil fill cap while engine is running—excessive blow-by indicates worn rings

- Check for oil leaks around seals and gaskets

- Listen for unusual valve train noise

Hydraulics and loader:

- Front axle seal leaks are common in loader tractors (check for oil residue)

- Operate loader through full range—jerky movement suggests contaminated fluid

- Test PTO clutch engagement—should be smooth, not chattering or slipping

Hours vs. condition:

- Under 500 hours: Essentially still breaking in

- 500–1,500 hours: Prime used territory

- 1,500–3,000 hours: Verify maintenance records carefully

- Over 3,000 hours: Approaching major service intervals (be prepared for costs)

The title trap: Verify clear title and that serial numbers match documentation. Tractor theft is more common than most buyers realize.

Maintenance & Ownership Reality: What Nobody Tells You at the Dealership

Tractor ownership involves more than changing oil. Understanding the maintenance reality, especially modern emissions systems helps you avoid costly surprises.

Diesel Particulate Filters (DPF) & Regeneration: The Under-25 HP Advantage

Any diesel tractor above 25 HP manufactured after 2015 includes emissions equipment: diesel particulate filters (DPF) and periodic regeneration cycles.

Here’s what that means in plain English:

The DPF traps soot from your diesel exhaust. Periodically, your tractor needs to burn off this accumulated soot through “regeneration”—running the engine hot for 20–30 minutes. This happens automatically during normal operation if you’re working the tractor hard.

The problem for small farm owners: If you only use your tractor an hour or two at a time for light tasks, the engine never gets hot enough for complete regeneration. Incomplete regens lead to clogged DPF filters, reduced power, and expensive ($2,000+) cleaning or replacement.

Why under-25 HP tractors avoid this: EPA regulations exempt sub-25 HP diesel engines from DPF requirements. This is why models like the Kubota L2501 (24.8 HP) and similar tractors are so popular—you get modern reliability without emissions complexity.

If you need more than 25 HP: Plan to work your tractor hard enough to maintain proper operating temperature, or budget for occasional forced regeneration at your dealer.

Maintenance Schedule Snapshot

Realistic maintenance intervals for typical small farm use (100–200 hours annually):

Daily (before each use):

- Grease loader pivot pins

- Visual fluid level checks

- Inspect tires and loader mounting

First 50 hours (break-in service):

- Initial engine oil and filter change

- Transmission fluid check

- Wheel lug torque verification

- Critical for long-term reliability—don’t skip this

Every 100–200 hours:

- Engine oil and filter

- Air filter inspection/cleaning

- Hydraulic system check

Every 400–600 hours (the expensive service):

- Hydraulic fluid and filter replacement

- Transmission fluid service

- Fuel filter replacement

- Budget $400–$600 for dealer service

Annual (regardless of hours):

- Coolant system check

- Battery maintenance

- Grease all zerks thoroughly

Reality check: Most small farm owners accumulate 100–150 hours annually. That translates to annual oil changes and a major hydraulic service every 3–4 years. Budget roughly $300–$500 yearly for maintenance supplies and occasional dealer work.

The Dealer Proximity Factor: The #1 Tie-Breaker

I’ve saved the most important ownership consideration for last: dealer location matters more than any specification.

A tractor with perfect specs from a dealer 2 hours away becomes a nightmare when you need warranty work or parts. That “simple” hydraulic line replacement turns into a full day of logistics- trailer rental, driving, waiting, return trip.

Questions to ask before buying:

- How far is your nearest authorized dealer?

- Do they offer mobile service for on-site repairs?

- What’s their typical warranty work turnaround time?

- Are they adequately staffed, or consistently backlogged?

I’ve seen farmers choose a slightly less ideal tractor model because they had an excellent dealer 15 minutes away versus a “perfect” tractor with support 90 minutes distant. That’s the right decision. When your tractor is down during hay season or harvest, dealer proximity becomes priceless.

Comparison Table: At-a-Glance Specs for the Best Tractors for Small Farms

Here’s a quick reference comparing our top picks across critical specifications:

| Model | HP | Transmission | Loader Lift (lbs @ 24″) | Base Weight (lbs) | Best For |

|---|---|---|---|---|---|

| Kubota L2501 | 24.8 | Hydrostatic or Gear | 1,190 | 2,480 | Mixed-use small farms, all-around versatility |

| John Deere 3025E | 24.7 | Hydrostatic | 1,320 | 2,315 | Premium ergonomics, mowing, loader work |

| Massey Ferguson 1835M | 34.5 | Gear/Shuttle | 1,450 | 3,175 | Market gardens, row crops, tillage |

| Kioti CK3510 | 34.5 | Hydrostatic or Gear | 1,565 | 3,042 | Livestock operations, heavy loader work |

| John Deere 1025R | 23.9 | Hydrostatic | 830 | 1,808 | Small acreage, landscaping, convenience |

| Kubota BX23S | 23 | Hydrostatic | 880 | 2,127 | Subcompact with backhoe, 1–3 acres |

| TYM T264 | 26.5 | Hydrostatic or Gear | 1,235 | 2,645 | Value-focused, feature-rich base model |

*Specifications current as of late 2024. Verify with dealers as models and specs evolve.

Conclusion: Making the Best Choice for Your Small Farm

After 4,000+ words of specifications, comparisons, and recommendations, here’s what actually matters: The best tractor for your small farm is the one that matches your daily tasks, fits your budget, and comes from a dealer who’ll support you long-term.

Not the one with the most impressive brochure. Not the one your neighbor swears by. Definitely not the one with the brightest paint.

Your tractor selection process should follow this order:

- Define your primary task (loader work, tillage, mowing, livestock management)

- Match that task to an appropriate HP range and transmission type

- Verify dealer proximity and service quality in your area

- Compare 2–3 models that meet criteria #1 and #2

- Sit in the seat and operate the controls before buying

Remember that buying used can save money upfront but verify maintenance history carefully. Buying new with 0% financing often makes more financial sense than the used market’s inflated pricing, especially when you factor in warranty coverage.

Whether you choose a kubota, john deere, kioti, or any other brand mentioned in this guide, buy the right equipment for your operation—not someone else’s. A 25 HP compact tractor that perfectly suits your 8-acre hobby farm will outperform a 50 HP utility tractor that’s overkill for your needs.

Your Next Steps

Visit dealers during the off-season (late fall, winter) when salespeople have more time and are often more negotiable. Test drive tractors in conditions similar to your property—hills, tight spaces, whatever challenges your farm presents. And most importantly, talk to existing owners in your area about their dealer service experiences.

The tractor you choose today should still be serving your farm reliably 15–20 years from now. Take your time, do your research, and make the choice that sets your small farm up for long-term success.

Now get out there and find your perfect match. Your farm and your back will thank you.

Frequently Asked Questions

Is 25 HP enough for a small farm?

For most small farms between 5–20 acres, yes—25 HP provides sufficient power for standard tasks like mowing, light loader work, box blading, and running a 5-foot rotary cutter.

The key is understanding that torque matters more than peak horsepower for most farming tasks. Modern compact diesel engines deliver strong low-end torque, which is what pulls implements through soil and lifts heavy loads.

Where 25 HP struggles: Heavy tillage in clay soils, running large (6-foot+) implements, commercial-scale brush hogging, or handling multiple demanding tasks simultaneously. If your operation regularly requires these capabilities, consider the 30–40 HP range.

Should I get a cab or open station compact tractor?

Cabs provide:

- Climate control (heat in winter, AC in summer)

- Protection from dust, debris, and weather

- Reduced noise exposure during long work sessions

Trade-offs:

- $6,000–$10,000 additional cost

- Reduced clearance for working under trees or in barns

- More difficulty with loader work visibility

- Harder to clean implements or make quick adjustments

My recommendation: For small farm operations under 15 acres, open station with a ROPS (roll-over protection structure) and sun canopy handles 90% of situations. Save the cab premium for a larger implement or attachment. If you’re in extreme climates (deep snow winters, brutal summer heat) or running 200+ hours annually, the cab investment makes sense.

Backhoe: Useful tool or expensive paperweight?

Backhoes on compact tractors are expensive ($4,000–$7,000) and add significant weight. For most small farm owners, renting a mini-excavator for $250–350 per day makes more financial sense than owning a tractor-mounted backhoe.

When tractor backhoes make sense:

- You need to dig frequently (weekly fence post holes, regular drainage work)

- You’re in a remote area where equipment rental isn’t easily accessible

- You’re building extensive infrastructure over multiple years

When to rent an excavator instead:

- One-time projects (building ponds, major drainage installation)

- Deep digging (over 6 feet)—excavators are more capable

- Large-volume excavation work

The Kubota BX23S mentioned earlier integrates a backhoe exceptionally well for a subcompact if you’ve determined you genuinely need this capability. For most buyers, it’s an expensive add-on that sits unused.

What about 2WD vs. four-wheel drive?

Four-wheel drive adds $2,500–$4,000 to tractor cost. Is it necessary?

You need 4WD if:

- Working on slopes or uneven terrain regularly

- Operating in wet conditions or heavy snow

- Running ground-engaging implements in challenging soils

- Your property has hills exceeding 10–15 degrees

2WD works fine for:

- Flat to gently rolling properties

- Primary use is mowing and light loader work

- Sandy or loamy soils with good drainage

- Budget constraints are significant

The middle ground: Many farmers start with 2WD and add ballast weight (loaded tires, wheel weights) to improve traction. This is 40–50% as effective as 4WD at 15–20% of the cost. If you later determine you need 4WD, 2WD tractors maintain decent resale value.

How do I choose between John Deere and Kubota?

Both are excellent manufacturers with strong dealer networks and proven reliability. Your decision comes down to:

Choose John Deere if:

- You prioritize operator comfort and ergonomics

- You value resale value slightly above all else

- You prefer industry-standard green for farm aesthetic

- Your local Deere dealer provides exceptional service

Choose Kubota if:

- You want to avoid DPF complications (L2501 at 24.8 HP)

- You prefer slightly lower purchase prices for comparable specs

- You value Kubota’s reputation for simple, durable engineering

- Your local Kubota dealer is more accessible or responsive

The honest truth: At the compact utility tractor level, both brands will serve you reliably for decades with proper maintenance. Test-drive both, evaluate local dealer quality, and choose based on which feels better when you’re actually in the seat. Comfort matters when you’re spending hours working.